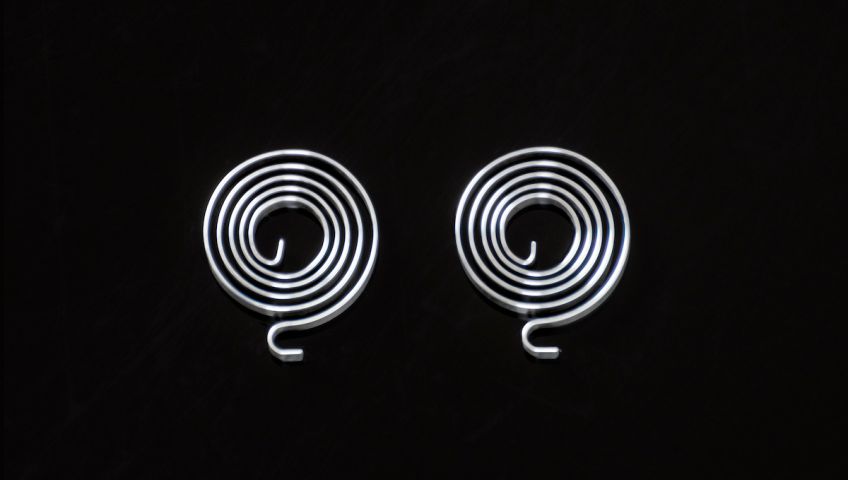

Suspension springs

The suspension springs are usually made of steel wire of circular cross section and wound helically. In special cases the wire can be conical or oval shape and the ends of the springs can have infinite variations and shapes.

Goal

The mission of the suspension springs is to absorb shocks and / or impacts that receives and transmits the wheel to the axle of the vehicle, be it car, motorcycle, agricultural vehicle etc etc.

Design & engineering

Muelles CROM designs and calculates a wide variety of special suspension springs for the range of vehicles on the market whatever they are.

You only need to know where anchors for the spring and the efforts that you wanna achieve

Raw materials

The materials of the suspension springs are one of the greatest assets of Muelles CROM and we manufacture them with very special qualities that require very good heat treatments from suppliers and highly regarded previously approved by our organization.

The suspension springs are mechanically brunt elements in a vehicle and also must add harsh elements like rain, grease, dirt, salt of public roads and highways.

That is why the corrosion protection whether it's painting as alkaline / electrolytic protection should be highly regarded as this could be a reason for a decline in the quality of performance and lead to breakage or plastic deformation by fatigue.

We recommend every 40,000 km review them as much and change every 100,000 km.

The suspension springs should always be rigged in the case of cars and never change just one of them.