SPRING DESIGN

Basic and elementary in the calculation and design of springs.

BASIC PRINCIPLES

There are three basic principles in spring design

- The heavier the wire, the stronger the spring

- The smaller the coil, the stronger the spring

- The more active coils, the less load you will have to apply in order to get it to move a certain distance.

ENGINEERING DEPARTMENT

& PROCESS OF MUELLES CROM

Compression Spring Software V3000 Copyright 2.013

Muelles CROM Design engineering + Compression Spring Software V15.64 #0410

Compression spring No.: 2098-4x32x120

Application : Hans ecker Maschinenelemente, Hanser Verlag

EN 10270-1 SH spring steel wire pat.drawn

Manufacturing : cold-coiled

Spring ends : lined-up and ground

Stress : static

Surface : drawn

Manufacturing compensation : no comment

adm.deviation De,Di,Dm : to DIN 2095 Quality Class 2

adm.deviation L0 : to DIN 2095 Quality Class 2

adm.deviation F1, F2 : to DIN 2095 Quality Class 2

adm.deviation e1, e2 : to DIN 2095 Quality Class 2

adm.deviation d : to DIN 2076 C

| modulus of elasticity | E | N/mm² |

206000

|

| shear modulus | G | N/mm² |

82000

|

| density | rho | kg/dm^3 |

7.85

|

| tensile strength | Rm | N/mm² |

1788

|

| adm.shear stress | tauz | N/mm² |

1001

|

| operating temperature | theta | °C |

20

|

| shear-modulus at working temperat. | G 20 | N/mm² |

82000

|

MAIN DIMENSIONS

| wire diameter | d | mm |

4 +/- 0.025

|

| inside diameter | Di | mm |

28

|

| mean coil diameter | Dm | mm |

32

|

| outside diameter | De | mm |

36 ± 0.5

|

| nos of coils | n(if) |

8.5

|

|

| inactive end coils lower side |

1

|

||

| inactive end coils upper side |

1

|

||

| Total number of coils | nt |

10.5

|

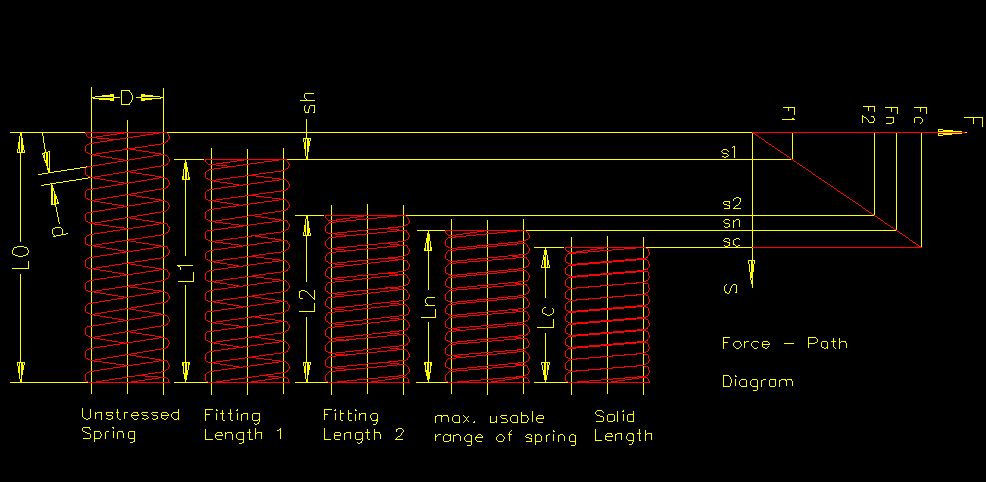

SPRING LENGTHS

| free length | L0 | mm |

120 ± 2.29

|

| spring length at load F1 | L1 | mm |

120

|

| spring length at load F2 | L2 | mm |

48.93

|

| usable spring length | Ln | mm |

48.93

|

| Solid length of spring | Lc | mm |

42.26 -0.262

|

SPRING LOAD

| spring load at L1 | F1 | N |

0 ± 21.6

|

| spring load at L2 | F2 | N |

669.5 ± 31.6

|

| spring load at Ln | Fn | N |

669.6

|

| spring load at Lc | Fc th | N |

732.4

|

SPRING TRAVELS

| stroke | sh | mm |

71.07

|

| spring travel | s1 | mm |

0.00

|

| spring travel | s2 | mm |

71.07

|

| usable spring travel | sn | mm |

71.07

|

| spring travel to Lc | sc | mm |

77.74

|

| Excursion until Buckling | sk | mm |

27.14

|

TENSIONS

| shear stress at F1 | tau 1 | N/mm² |

0

|

| shear stress at F2 | tau 2 | N/mm² |

852

|

| shear stress at Fn | tau n | N/mm² |

853

|

| shear stress at Fc th. | tau c | N/mm² |

932

|

| stress coefficient | k |

1.172

|

|

| corrected shear stress at F1 | tau k1 | N/mm² |

0

|

| corrected shear stress at F2 | tau k2 | N/mm² |

999

|

| adm. shear stress | tau z | N/mm² |

1001

|

| Bearing Application Coefficient | nue |

1

|

|

| Deviation of Surface Line | e1 | mm |

6

|

| Deviation of Parallelism | e2 | mm |

1.08

|

| spring rate | R | N/mm |

9.421

|

| natural frequency | fe | 1/s |

167.2

|

| Increase in Coil Diameter at Lc | deltaDe | mm |

0.436

|

| Minimum clearance of active coils | Sa | mm |

6.66

|

| Actual clearance of active coils | sc-s2 | mm |

6.67

|

| coiling ratio | w |

8

|

|

| Gradient ratio | tan alfa |

0.13

|

|

| Gradient | m | mm |

13.65

|

| Gradient ratio | Dm/m |

2.34

|

|

| Lean grade | lambda |

3.75

|

|

| spring energy between s1 and s2 | W12 | Nmm |

23792

|

| weight of the spring | m | g |

104.1

|

| wire length | L | mm |

1056

|

| pressure | R/D | N/mm² |

0.294

|

| Max.diameter of bedding mandrel | Ddmax | mm |

27.48

|

| Minimum diameter of bore | Dhmin | mm |

36.96

|

REMARKS, WARNINGS AND ERROR MESSAGES

| Warning: bending ! |

| bending of the spring before extension 2 is reached. (see bending diagram) |

| the bending security will be improved by better bedding, larger coil diameter Dm, smaller spring lemgth L0 |

| Warning: setting þ2/þz=0.85) |

| tension tau2 is more than 70% of tau perm, after a time the spring forces will be reduced. |

| increase wire diameter, use material of higher strength. |

¿Do you like? ¡Share!

Author: Muelles Crom

MUELLES CROM was founded in 1953 in Granollers. We currently have production facilities in Granollers and Les Franqueses del Vallès.